How to Protect Wind Turbines with Mobil Industrial Lubricants?

How to Protect Wind Turbines with Mobil Industrial Lubricants?

How to Protect Wind Turbines with Mobil Industrial Lubricants?

Renewable energy is getting a bigger and bigger market share world-wide. A major component in this kind of energy is represented by the one obtained in wind farms and Romania has a great potential in this field. Just as shown in the Ernst & Young report "Renewable energy country attractiveness index" (The February 2013 edition), our country is ranked 10th in the world regarding its wind energy potential. A proof is also the total wind energy capacity which exceeded 2000 MW in 2013, according to the "Wind energy and other renewable energy sources in Romania" report.

Surely the wind turbines come hand in hand with problems particular to their working conditions. See below how Mobil Industrial Lubricants help you get over the issues that can occur with wind turbines.

1. Complex Equipment with Particular Requirements

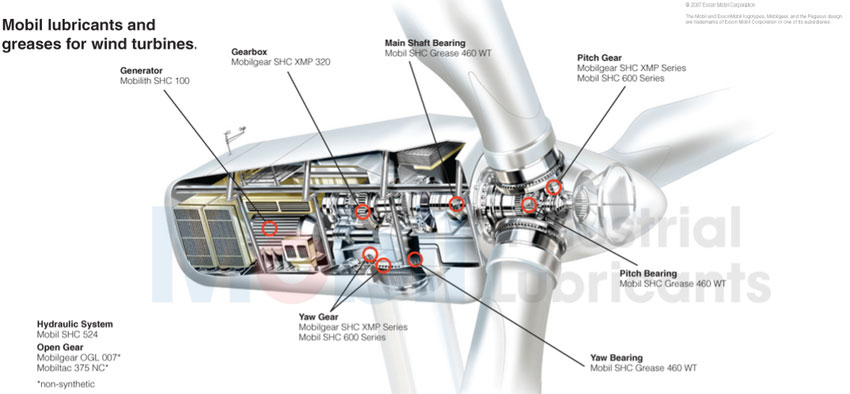

Wind turbines have a complex system where every component has its own specific lubrication requirements. ExxonMobil has developed products that help every component work at maximum capacity: from the hydraulic system, to the yaw and pitch bearings and gear. Thus, by using the lubricant available in Romania through Star Lubricants, the entire system will be truly productive. Please see below how the inside of a wind turbine looks like and what products are appropriate for every component:

2. Extreme Operating Conditions

Wind turbines are installed in harsh environments. For instance, the turbine engine is located at approximately 300 meters high, thus the high wind can affect its components. Also, the fact that the wind turbines work in open spaces makes them more prone to degradation due to the weather (high wind, rain). In order to guard the turbines from these issues, Mobil lubricants have a strong protective components and their use helps increase their functioning security and avoid unplanned idle times.

3. Costly Maintenance

Being a complex system, turbine maintenance can be expensive. Also, idle times necessary for maintenance operations will affect their productivity. Mobil lubricants for wind turbines have the potential to increase fuel change periods which leads to rarer idle times and a production of energy at maximum capacity. For instance, Mobil SHC oils can resist up to 6 times more than mineral oils, thanks to the fact that they offer a great stability and resistance to oxidation. This helps increase oil change intervals and reduce costs related to the disposal of used oil.

The forecast shows that the wind farm in Romania will continue to develop a lot in the following years and the lubricants used for the maintenance of wind turbines will follow the same path. In order to be up to date with the latest news in this field, Star Lubricants will participate between the 26th and the 28th of September 2014 to the Wind Technology Days, event hosted by Monsson in the Danube Delta.

For more information on the Mobil industrial lubricants for wind turbines, click the image below and get contact information for the Star Lubricants agents ready to answer your questions.